Sustainable Oil Sludge Cleaning: Revolutionizing Sludge disposal

Are you still relying on outdated methods like heat for oil sludge cleaning? Consider a more sustainable alternative. Envorem introduces a groundbreaking solution that harnesses the power of water for oil sludge treatment and soil remediation.

Solution.

It’s all about water.

Oily sludge is a viscous, sticky mess. It is almost impossible to pump and is a hazardous waste that no-one wants.

The usual disposal routes for these wastes is incineration or dumping into open pits. However, pits just procrastinate the problem as the sludge will not go away and will eventually have to be incinerated generating colossal quantities of CO2 – around 1.1 tonnes per tonne incinerated. [ref1]

Envorem has developed an innovative new technology that combines hydraulic shock with a little-known phenomenon in water called cavitation to process production sludges, cleaning the solids and recovering the entrained oil - all without generating emissions.

We have completed highly successful pilots in both Saudi Arabia with Aramco, and in Oman for their National Oil Company (PDO). Both pilots proved the technology generates a fraction of the emissions of thermal treatment and is both cheaper & faster. At Aramco’s Shaybah facility, our on-site system cut sludge transport, reduced waste by 97%, and lowered disposal costs by 40%. At PDO’s Oman trial, 99% of oil was recovered as usable crude, reducing extraction needs and emissions - a double benefit; reducing the need for extraction and its associated carbon footprint, plus saving emissions from disposal by incineration. Furthermore, this demonstrated that if the value of recovered oil is included, costs are potentially net positive providing a financial as well as environmental case for change in practice.

So what’s the secret?

Well, you will understand that we don’t share too much even though our process is now patented but….

Envorem has combined established techniques with hydraulic shock and cavitation, where bubbles are created by the vaporisation of water, a phenomenon copied from the natural world [ref2].

🫧 Cavitation 🫧

Cavitation can be generated ultrasonically, electrically or physically and is widely known as a parasitic effect that destroys propellers on ships and the impellers of pumps. The collapse of cavitation bubbles is so powerful it liberates fragments of metal from the surfaces.

Pump impeller with cavitation damage

Sounds incredible?

Here is a link to a great video by Richard Hammond (Top Gear UK presenter) explaining the power of cavitation.

Envorem harnesses these forces to create a water-based system that disassembles the sludge and strips oil contamination from particle surfaces. At the core of the system, millions of cavitation bubbles are artificially generated within the target material. These bubbles collapse with incredibly high forces, forming microscopic water jets and shock waves that impact surfaces of solids and generating localised temperatures of up to 3,000oC.

The great news is that because all cavitation occurs at a microscopic level, the energy is highly focussed making the process highly energy-efficient and really fast! As the hydrocarbons are physically removed rather than burnt, all this occurs without generating emissions. (Other than the small emissions from our energy usage).

⚡︎ SHOCK ⚡︎

Hydraulic

The capacity of water jets to clean, soft material from hard surfaces is well known and the concept of using high levels of kinetic energy and hydraulic shock delivered by water with various engineered techniques for industrial cleaning, is well established. Pressure washers for domestic use are now also commonplace providing effective cleaning of hard surfaces with the addition of little or no chemicals.

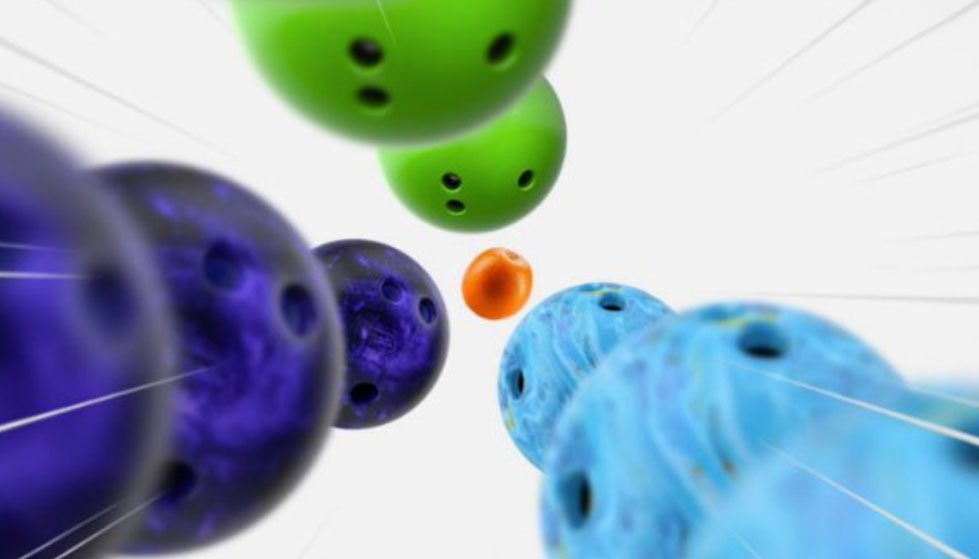

The Envorem technology takes this a new level focussing water energy into a processing chamber equivalent to, every second, firing three 6kg bowling balls at 2/3 of the speed of an airliner into a chamber the size of orange.

Clumps of particles are instantly disassembled, and hydrocarbons ripped from the target material surfaces, both by the microjet impact and kinematic viscosity as the particles are accelerated. Liberated hydrocarbons and other contaminates are transferred from the particles to the water phase.

Combining this effect with cavitation and other physical processes, Envorem has created a system that is clean, fast, and inexpensive.

A benefit that is key to encouraging a change of practice by the oil industry, is that the oil and water is recovered and can be recycled [ref3]. This potentially makes adopting cleaner practices a profitable activity!

We have already tested our technology processing at 50 tonnes sludge per hour - some 10 times the capability of thermal treatment plants and using 95% less energy [ref4], all in a system that is small enough to be mobile; contained in several trucks. A fixed plant could easily be scaled to process 10-50 times this figure putting into viable reach some of the massive clean-up challenges the oil industry faces. And, with the process being relatively inexpensive there is no longer a reason not to do it!

Bench Scale Trial Results

The sand was cleaned to <1000PPM (10 times better than required by Oman standards)

The amazing effect of the cavitation bubbles is to clean very small particles that if impacted with hydraulic shock in water, would just move with the water. The cavitation shock waves propagate at lightning speed – too fast for the particles to escape. As shown in the picture, the sub 125 micron particles are clean.

Results: Weathered Sand From Kuwait

(sample provided by Kuwait Oil Company)

After (<0.1% oil)

Before (5%oil)

5% oil at the start and <0.1% TPH post-processing (10 times better than standard required)

Testing and results

Having proven the technology at bench scale, the system was then scaled up to a 50-tonne per hour test to verify performance at high throughput. Sludge for the trial was synthesised by making a sludge from 25% heavy fuel oil and fine sand. The oil was recovered and the TPH of the cleaned sand was less than 2000ppm (0.2%).

Subsequently, Envorem was awarded a pilot project in Oman as a field trial, and most recently, a further pilot with the largest oil company in the World, Aramco.

The equipment is built into 40ft transportable containers for plug & play set-up on site allowing it to be sited close to the waste source.

The results from the pilot were that:

The system operated at a steady state of 2 tonnes sludge or soil per hour

>99% of the hydrocarbons were recovered

Solids were cleaned to <5000 PPM TPH (standard required was 10,000)

Envorem’s 5-tonne per hour pilot unit

We believe the power of our technology can be used to clean oily sludge from a whole range of sources and industries; we are looking forward to working with companies with the vision to clean up the world’s oil pollution.

Get in touch now and let’s discuss how we can work together for a cleaner planet!